ATEX Directive for explosive atmosphere

European ATEX Directive 2014/34/EU for the regulation of equipment and systems for explosive atmosphere

When designing air pollutant extraction and abatement equipment, it is essential to consider the characteristics of the production system and the pollutants emitted. As we have seen in a previous article on explosive dust, many industrial processes involve the use of substances that can cause deflagrations. Systems must therefore be designed and constructed in accordance with the ATEX Directive 2014/34/EU (ATEX compliance). Let us take a look at the main details of the new ATEX Directive.

ATEX Directive: meaning and scope

On 29 March 2014, the New ATEX Directive 2014/34/EU was published in the Official Journal of the European Union, which repealed the previous ATEX Directive 94/9/EC as of 20 April 2016. In Italy, the transposition of this ATEX Directive took place through Legislative Decree No. 85 of 19 May 2016.

With the ATEX regulations, the European Union has defined the necessary safety requirements for all equipment and protective systems intended for use in potentially explosive atmospheres. This product directive directly addresses manufacturers with the aim of ensuring the free movement of these goods within the European Union. Furthermore, the ATEX directive is also extended to all safety, control and regulation devices that are not used in an explosive atmosphere, but are necessary for the operation of the systems.

For the purposes of the ATEX regulations, the following definitions apply:

- «equipment» means machines, apparatus, fixed or mobile devices, control components and instrumentation thereof and detection or prevention systems which, separately or jointly, are intended for the generation, transfer, storage, measurement, control and conversion of energy and/or the processing of material and which are capable of causing an explosion through their own potential sources of ignition;

- «protective systems» means devices other than components of equipment which are intended to stop incipient explosions immediately and/or to limit the effective range of an explosion and which are separately made available on the market for use as autonomous systems;

- «components» means any item essential to the safe functioning of equipment and protective systems but with no autonomous function;

- «assembly» means a combination of two or more pieces of equipment and any components placed on the market and/or put into service by a responsible person (manufacturer) in the form of a single functional unit;

- «explosive atmosphere» means a mixture with air, under atmospheric conditions, of flammable substances in the form of gases, vapours, mists or dusts in which, after ignition has occurred, combustion spreads to the entire unburned mixture;

- «potentially explosive atmosphere» means an atmosphere which could become explosive due to local and operational conditions.

ATEX Directive: description of economic operators and their obligations

The new ATEX Directive h\as not entailed any particular changes to the technical contents of the ATEX Directive 94/9/EC, but it has brought the obligations of the various figures involved in the production and marketing of products intended for installation in explosion risk zones more clearly into line with the new legislative framework (Decision 768/2008/EC). Let us look together at the figures involved and their obligations.

- «manufacturer» means a natural or legal person who manufactures a product or has it designed or manufactured and markets it under his name or trademark or uses it for his own purposes. Among other tasks, manufacturers must ensure that products are manufactured in conformity with the essential health and safety requirements, prepare technical documentation, carry out (or have carried out) the conformity procedure, affix the explosion protection mark and a type/serial/batch number to enable identification;

- «authorised representative» means a natural or legal person established in the Union who has received a written mandate from a manufacturer to act on his behalf in relation to specified tasks. These mainly concern the relationship with the authorities and the making available of the EU Declaration of Conformity and the technical documentation;

- «importer» means a natural or legal person established in the European Union who places a product from a third country on the EU market. Among other obligations, he must place compliant products on the market by verifying that the manufacturer has carried out the specific procedure and prepared the technical documentation and that the CE marking and required documents are present;

- «distributor» means a natural or legal person in the supply chain, other than the manufacturer or the importer, who makes a product available on the market. Before placing a product on the market, in addition to other obligations, they must verify the presence of the CE marking and the required documents; ensure that storage and transport conditions do not compromise conformity.

ATEX compliance: conformity assessment

As we have seen in the previous paragraph, the manufacturer is the person who must ensure the conformity of the equipment/system or component being assessed.

Annexes III to IX of the ATEX Directive describe the conformity assessment procedures, which include: EC type-examination, single product verification and internal production control. The latter, often wrongly referred to as “self-certification”, presupposes an independent assessment by the manufacturer of the conformity of the product he intends to place on the market.

Whichever procedure is adopted, all formal and informal steps must be completed by the manufacturer and include:

- drawing up the technical file;

- product testing and trials;

- use and maintenance manual;

- declaration of conformity;

- CE marking

At the end of the conformity assessment process, the manufacturer must issue the declaration of conformity, which must contain the following elements:

- Standards or identification mark of the manufacturer or his authorised representative in the European Community;

- Description of the apparatus, system and device;

- Identification of all parts making up the assembly;

- Any name and number of the Notified Body involved;

- Any references to harmonised standards;

- Any references to specifications used;

- Any references to other directives applied;

- Identification of the signatory

The Declaration of Conformity must be followed by the CE Marking, for details please read the dedicated article.

ATEX: groups and categories

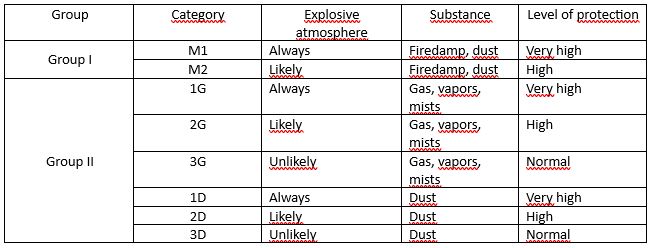

There are several assessment procedures as seen above, but how does the manufacturer choose which one to refer to? To answer this question, it is necessary to point out that, as specified in Annex 1 of the ATEX directive, products are divided into two groups:

- Group I consisting of equipment that is intended for use in the underground parts of mines and in their surface installations. In these environments, the explosion hazard is generated by the possible presence of firedamp gas and/or combustible dust;

- Group II comprises equipment intended for use in all other places where there is a risk of explosion.

The choice of conformity assessment procedure is made on the basis of this classification and also taking into account the categories to which the equipment belongs. The two groups described above are further subdivided according to the level of safety guaranteed by the equipment.

Specifically, Group I is divided into category M1 and M2, while Group II is divided into category 1, category 2 and category 3. Let’s look at the details together:

- Category M1 (Group I) = equipment providing a very high level of protection, remaining operational in an explosive atmosphere even in the event of an exceptional fault;

- Category M2 (Group I) = equipment providing a high level of protection, but in the event of an explosive atmosphere, the power supply must be interrupted;

- Category 1 (Group II) = equipment providing a very high level of protection and which is intended for use in areas in which an explosive atmosphere is present at all times, frequently or for long periods. This equipment must guarantee the required safety even in the event of its failure;

- Category 2 (Group II) = equipment designed to ensure a high level of safety in an environment in which an explosive atmosphere is likely to occur. Such equipment must be equipped with means of protection to ensure the required standard even in the event of recurring faults or malfunctions which must normally be taken into account;

- Category 3 (Group II) = equipment providing a normal level of protection and intended for an environment in which an explosive atmosphere is unlikely to occur. In this category, it is sufficient that the equipment ensures safety during normal operation.

Equipment in Group II is then subdivided according to the type of substance giving rise to the ATEX explosive atmosphere: in the case of dusts, the letter D is shown after the category (1D, 2D or 3D) in the equipment marking, while in the case of gases, vapours and oil mists, the letter G is shown (1G, 2G or 3G).

ATEX regulations: conclusions

As we have seen, the ATEX Directive is very broad and affects many industries. When dealing with ATEX explosive atmospheres, it is very important to choose consultants and suppliers with the right experience in the field. At Tecnosida we design and build systems for the treatment of air pollutants specifically tailored to the specific needs of our customers: in over 40 years of experience we have created countless ATEX systems applied in explosive atmospheres with excellent results! Contact us for an inspection without obligation!