Machinery Directive 2006/42/CE

Legislative study

The machinery directive, or MD (Machinery Directive), is a set of rules aimed at manufacturers of machines and partly completed machinery marketed and used in the European Union.

With this directive, the EU establishes the Essential Safety Requirements (RES) in order to:

- allow the free movement of machines within the European market;

- ensure the safety and protect the health of users

Directive 2006/42/EC (also known as “New Machinery Directive” as it replaces the previous 98/37/EC) was implemented in Italy by the Legislative Decree of January 27, 2010 and entered into force throughout Europe starting from December 29, 2009.

Which products are affected by the EU directive 42/2006?

As it can be seen from the name, and as we have anticipated in the previous paragraph, the machinery directive has as its object machines and partly completed-machines. But in detail what is the field of application?

To answer this question we refer directly to the text of Directive 2006/42/EC where the products affected by the legislation are specified and defined:

- machinery;

- interchangeable equipment;

- safety components;

- lifting accessories;

- chains, ropes and webbing;

- removable mechanical transmission devices;

- partly completed machinery.

Detailed definitions of the products covered by the machinery directive

Definition of machine according to directive 2006/42/EC

In the aforementioned regulation the machine is defined as “an assembly, fitted with or intended to be fitted with a drive system other than directly applied human or animal effort, consisting of linked parts or components, at least one of which moves, and which are joined together for a specific application”.

In Article 2, letter a of the directive, further specifications are set out on this point. For more information, find here the complete text of DIRECTIVE 2006/42/CE OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL.

Definition of partly completed machinery according to directive 2006/42/EC

The directive defines partly completed machinery as “an assembly which is almost machinery but which cannot in itself perform a specific application. Partly completed machinery is only intended to be incorporated into or assembled with other machinery or other partly completed machinery or equipment”

Definition of interchangeable equipment according to directive 2006/42/EC

Their definition in the norm is: “a device which, after the putting into service of machinery, is assembled with that machinery by the operator himself in order to change its function or attribute a new function, in so far as this equipment is not a tool”

Definition of safety components according to directive 2006/42/EC

The safety components according to 2006/42 are: “a component which serves to fulfil a safety function”

Definition of lifting accessories according to directive 2006/42/EC

In the text of the directive they are identified as “component or equipment not attached to the lifting machinery, allowing the load to be held, which is placed between the machinery and the load or on the load itself, or which is intended to constitute an integral part of the load and which is independently placed on the market; slings and their components are also regarded as lifting accessories”

Definition of chains, ropes and belts according to directive 2006/42/EC

The standard defines them as “chains, ropes and webbing designed and constructed for lifting purposes as part of lifting machinery or lifting accessories”

Definition of removable mechanical transmission devices according to directive 2006/42/EC

They are described, in the quoted text, as “removable component for transmitting power between self-propelled machinery or a tractor and another machine by joining them at the first fixed bearing”

Obligations of the manufacturer and requirements of the machines

After analyzing the products covered by the machinery directive, the time has come to focus on annex 1 which specifies the manufacturer’s obligations and the safety requirements (RESS) that the machines must satisfy in order to be marketed and used within the European Community. In fact, the directive 2006/42/EC specifies the parameters to be used for the construction of the machines and it is established that the manufacturer has the obligation to accompany the machines with the documentation described in the following paragraphs.

The technical file according to 2006/42/EC

The Annex VII of the Machinery Directive is dedicated to the technical file: the technical file is a document that must include all information necessary to demonstrate that the machine meets all the safety requirements (RESS) present in Annex I.

The technical file must contain:

- general description of the machine

- overall and detailed drawing of the machine

- diagrams of the control circuits

- documentation referred to risk assessment

- standards and technical specifications applied

- technical report with the results of the tests carried out

- copy of the EC declaration of machine compliance and instructions.

As required by law “The technical file must be made available to the competent authorities of the Member States for at least 10 years from the date of manufacture of the machine or of the last unit produced in the case of series production. Failure to submit the technical file following a duly motivated request by the competent national authorities may constitute sufficient reason to doubt the compliance of the machine in question with the essential safety and health protection requirements. ”

We will discuss this in the section dedicated to the organs supervision and sanctions.

Instruction manual for use and maintenance according to 2006/42/EC

The manual, together with other sources of information present on the machine (such as signs, signaling devices and man-machine interfaces), provides the user with all the information necessary for using the machine in safe conditions. As required in point 1.7.4 of Annex I (Essential Health and Safety Requirements) of the Machinery Directive, it must be translated into the official Community language of the Member State in which the machine is placed on the market or put into service and must contain at least the following information:

- the business name and full address of the manufacturer and of his authorized representative;

- the designation of the machinery as marked on the machinery itself, except for the serial number;

- the EC declaration of conformity, or a document setting out the contents of the EC declaration of conformity;

- a general description of the machinery;

- the drawings, diagrams, descriptions and explanations necessary for the use, maintenance and repair of the machinery and for checking its correct functioning;

- a description of the workstation(s) likely to be occupied by operators;

- a description of the intended use of the machinery;

- warnings concerning ways in which the machinery must not be used that experience has shown might occur;

- assembly, installation and connection instructions, including drawings, diagrams and the means of attachment and the designation of the chassis or installation on which the machinery is to be mounted;

- instructions relating to installation and assembly for reducing noise or vibration;

- instructions for the putting into service and use of the machinery and, if necessary, instructions for the training of operators;

- information about the residual risks that remain despite the inherent safe design measures, safeguarding and complementary protective measures adopted;

- instructions on the protective measures to be taken by the user, including, where appropriate, the personal protective equipment to be provided;

- the essential characteristics of tools which may be fitted to the machinery;

- the conditions in which the machinery meets the requirement of stability during use, transportation, assembly, dismantling when out of service, testing or foreseeable breakdowns;

- instructions with a view to ensuring that transport, handling and storage operations can be made safely, giving the mass of the machinery and of its various parts where these are regularly to be transported separately;

- the operating method to be followed in the event of accident or breakdown;

- if a blockage is likely to occur, the operating method to be followed so as to enable the equipment to be safely unblocked; L 157/48 Official Journal of the European Union EN 9.6.2006

- the description of the adjustment and maintenance operations that should be carried out by the user and the preventive maintenance measures that should be observed;

- instructions designed to enable adjustment and maintenance to be carried out safely,including the protective measures that should be taken during these operations;

- the specifications of the spare parts to be used, when these affect the health and safety of operators;

information on airborne noise emissions; - where machinery is likely to emit non-ionising radiation which may cause harm to persons,in particular persons with active or non-active implantable medical devices, information concerning the radiation emitted for the operator and exposed persons

The instructions play a fundamental role in safeguarding the health of the operators and for this reason they must be drawn up before the machine is placed on the market and/or put into service. As required by the machinery directive, the manufacturer/distributor must ensure that the end user receives these instructions. Given the importance of the information for use, their preparation is regulated by various rules which over the years have complemented the provisions in point 1.7.4 of Annex I of the machinery directive. Among them we find:

- ISO 12100: 2010 “Safety of machinery – General design principles – Risk assessment and risk reduction”: defines the general design methods and the principles that manufacturers must follow for risk assessment and risk reduction. The drafting of the instruction manual is closely linked to the risk assessment as the latter allows identifying the hazards and estimating the risks that arise during the life cycle of the machine. The goal is to eliminate these dangers/get to sufficiently reduce risks

- CEI EN 82079-1: 2013 (IEC 2012) “Preparation of information for use (instructions for use) of products – Part 1: Principles and general requirements”: provides general principles and detailed requirements for the creation of all types of instructions for use intended for any product. Among them we also find those relating to the construction of machines and semi-machines

- ISO 20607: 2019 “Safety of machinery – Instruction manual – General drafting principles”: specifies in detail the requirements that an instruction manual must have for the products falling within the scope of the Machinery Directive

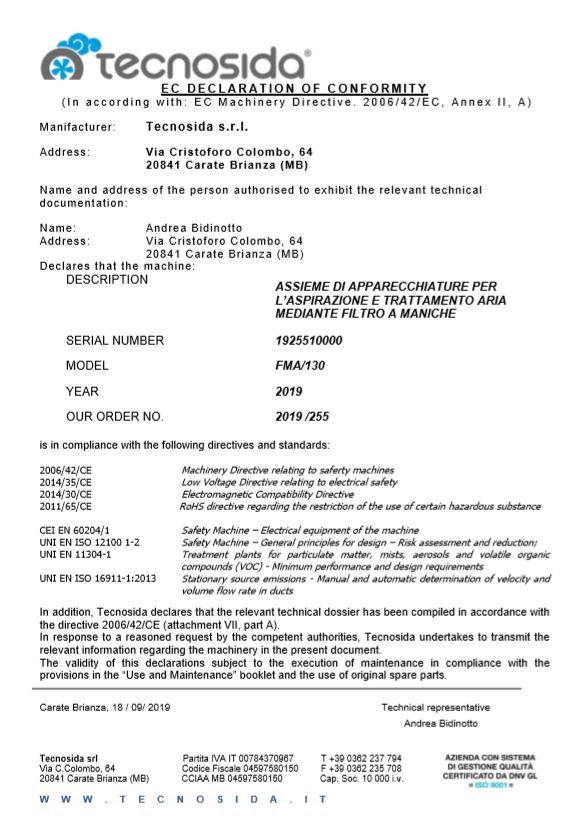

What is a declaration of conformity according to 2006/42/EC ?

The declaration of conformity is the act whereby the manufacturer declares, under his own personal responsibility, that the product complies with the essential safety requirements of Directive 2006/42/EC.

This document must be typed or clearly written in the same language as the original instructions for use and must be accompanied by a translation in the language of the country of use. The declaration can be inserted in the instructions for use or it can be a separate document, and must contain the following elements:

- business name and full address of the manufacturer and, where appropriate, his authorised representative;

- name and address of the person authorised to compile the technical file, who must be

established in the Community; - description and identification of the machinery, including generic denomination, function, model, type, serial number and commercial name

- a sentence expressly declaring that the machinery fulfils all the relevant provisions of Machine Directive and where appropriate, a similar sentence declaring the conformity with other Directives;

- where appropriate, the name, address and identification number of the notified body which carried out the EC type-examination referred to in Annex IX and the number of the EC type-examination certificate;

- where appropriate, the name, address and identification number of the notified body which approved the full quality assurance system referred to in Annex X;

- where appropriate, a reference to the harmonised standards used;

- where appropriate, the reference to other technical standards and specifications used;

- the place and date of the declaration;

- the identity and signature of the person empowered to draw up the declaration on behalf of the manufacturer or his authorised representative.

The Directive requires that the drafting of the declaration of compliance should be performed by a notified body only if the machine falls between the categories present in Annex IV (such as, for example, some types of saws or presses). In this case we speak of an EC type examination, or the procedure according to which a notified body verifies and certifies that a representative model of a machine in Annex IV meets the requirements of Directive 2006/42/EC. For all other machines, a self-certification is sufficient with which the manufacturer declares their compliance with the requirements of the Directive and any additional legislation that may be applicable to it.

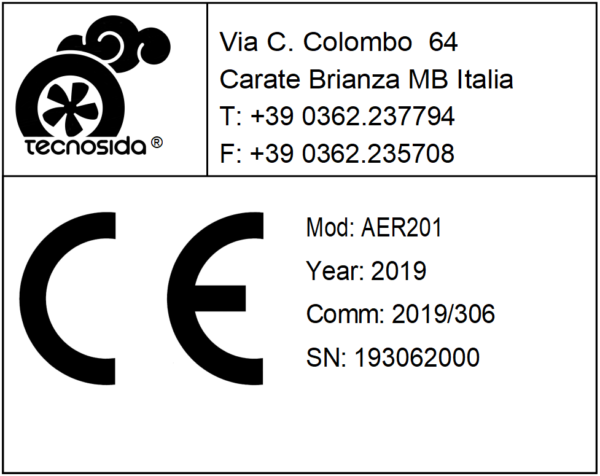

CE Marking according to 2006/42/EC

The CE marking is affixed to machinery deemed to comply with the Machinery Directive and with it the manufacturer/distributor assumes responsibility for the product, allowing access to the market and free movement. This system allows the competent authorities to identify non-compliant products.

As established by the directive in Annex 1, each machine must bear the following information in a “visible, legible and indelible” manner: company name and address of the manufacturer, CE marking, designation of the machine and series or type, year of construction. In the event that the machine is intended for use in a potentially explosive area, it must bear: Brand Ex, group to which the dangerous substance being considered belongs, category of the environment in which the equipment is located (M1, M2 for mines or 1,2,3 in environments other than mines) and the type of dangerous pollutant found in the environment (G = gas, D = dust). Annex 1 of the directive also establishes that the method of applying the marking must be permanent as well as the connection to the machine (welding, riveting or gluing).

It is therefore usually printed on a metal or adhesive plate which is applied to the machine and which contains the information relating to the manufacturer, the machine and the CE mark. The latter must then respect the proportions set out in Annex III of the directive. For more details on this, please keep the machinery directive as a reference.

Supervisory bodies and sanctions referred to directive 2006/42/EC

After analyzing the directive 2006/42/EC and the obligations of the machine manufacturer, we conclude this legislative study with a brief mention of the control activities aimed at verifying the conformity of the documentation and the machines with the directive. The checks are carried out by the Supervisory Bodies (ASL, ARPA, provincial labor departments…) during periodic inspections or following accident reports and, in the event that deficiencies emerge of the essential safety requirements of a machine, a report must be made to the Ministry of Economy. The report is taken into consideration by the Inter-ministerial Committee which entrusts the technical assessment to the GLAT (Technical Assessments Working Group) which verifies it taking into account the opinion of the technician in charge of the assessments, the existing technical documentation and the opinions expressed in similar cases.

If the report is deemed irrelevant or incomplete, the MSE (Ministry of Economic Development) requests further checks from the territorial supervisory bodies that had submitted it. On the other hand, when the report is considered valid, a registered letter is sent to the manufacturer asking them what steps it intends to take to resolve the problem and the complete list of machines placed on the market. In cases where this procedure is not sufficient, checks are carried out at the manufacturer and the machine’s Technical File is examined. If after the investigation, it is confirmed that the machine does not comply with the RES (Essential Safety Requirements), the manufacturer must take the necessary measures and update the list of machines in circulation to allow their possible withdrawal in case of confirmed danger. Manufacturers and stakeholders affected by the Machinery Directive are then subject to administrative and pecuniary sanctions established by Legislative Decree 81/2008.

Don’t miss our updates! Sign up to our newsletter!