ATEX meaning and application

ATEX meaning and its application in the industrial sector

ATEX is a word we often hear in the industrial field, especially when new machinery or systems are to be purchased, but what is the meaning of ATEX? Find out with us by reading our dedicated article.

ATEX meaning and operator safety

ATEX is the acronym of the French words “ATmosphères EXplosibles”, which in Italian is translated as “Atmosfera Esplosiva”. Italian Legislative Decree 81/08 (Art. 288) defines this term as a mixture with air, under atmospheric conditions, of flammable substances in the form of gases, vapours, oil mists or dusts in which, after ignition has occurred, combustion spreads to the entire unburned mixture.

To simplify, we can say that an explosive atmosphere is a mixture characterised by gases and/or dusts which, under certain conditions, can give rise to explosions. An atmosphere that is likely to develop into an explosive atmosphere due to local and/or operational conditions is called a “potentially explosive atmosphere“.

In the industrial sector, there are many substances that can give rise to explosive phenomena. In particular, they can be generated by:

- gases, vapours and mists given off by paints, thinners, glues, resins, chemical reactions and the like;

- dusts emitted by processes involving metals and alloys, wood, plastics, carbon fibre, substances of organic origin (flour, seeds, sugar, etc.) and the like.

In the light of the above, it is easy to understand that there are many companies potentially affected by explosion risk. Considering that this phenomenon represents a potential risk to workers’ health and safety and to the environment, it is essential to know the ATEX meaning and take all necessary measures to prevent and manage these events. Maximum attention must also be paid to the design and construction of air pollutant extraction and treatment systems, which must be equipped with essential components for explosion management. Only with correct execution can risk be reduced and operators protected. For more information on the design of ATEX systems, please read the dedicated article here.

ATEX: directives and technical standards

At the regulatory level, there are many laws that define the guidelines to be adopted on health and safety against the risk of explosive atmospheres. Among them are:

- Italian Legislative Decree 81/2008, also known as the Consolidated Occupational Health and Safety Act, amended by Italian Legislative Decree no. 106 of 3 August 2009;

- ATEX Directive 2014/34/EU containing provisions concerning equipment and protective systems intended for use in potentially explosive atmospheres;

- social directive 99/92/EC (ATEX Directive 137) defining minimum health and safety requirements for workplaces with potentially explosive atmospheres

Two technical standards were then defined that classify hazardous places due to the presence of explosive dusts and gases. They are:

- EN 60079-10-1:2016 for the presence of gases;

- EN 60079-10-2:2016 for the presence of combustible dust.

For further information on the ATEX directive 2014/34/EU, please read the dedicated article.

ATEX: zone classification

So far, we have given an overview of the meaning of ATEX, also referring to the laws regulating potentially explosive atmospheres. As we have mentioned, work areas must be classified into zones (CEI EN 60079-10) according to the frequency and duration of explosive atmospheres: this aspect is essential for determining the characteristics of equipment intended for use in ATEX zones.

Let us look at this important classification together:

- Zone 0: a place in which an explosive atmosphere consisting of a mixture of air and flammable substances in the form of gas, vapour or mist is present continuously or for long periods or frequently;

- Zone 1: a place in which an explosive atmosphere consisting of a mixture of air and flammable substances in the form of gas, vapour or mist is likely to occur in normal operation;

- Zone 2: a place in which an explosive atmosphere consisting of a mixture of air and flammable substances in the form of gas, vapour or mist is not likely to occur in normal operation but, if it does occur, will persist for a short period only;

- Zone 20: a place in which an explosive atmosphere in the form of a cloud of combustible dust in air is present continuously or for long periods or frequently;

- Zone 21: a place in which an explosive atmosphere in the form of a cloud of combustible dust in air is likely to occur in normal operation occasionally;

- Zone 22: a place in which an explosive atmosphere in the form of a cloud of combustible dust in air is not likely to occur in normal operation but, if it does occur, will persist for a short period only.

All air pollutant extraction and treatment systems, as well as inspection equipment such as explosion-proof cameras, must be designed and constructed according to the specific characteristics of the areas described above. In this way, possible explosions can be prevented and managed in the best possible way.

Fire triangle and explosion pentagon

Before concluding this article, it is necessary to make a further clarification: so far we have talked about dust and gas, but explosions do not occur in the same way!

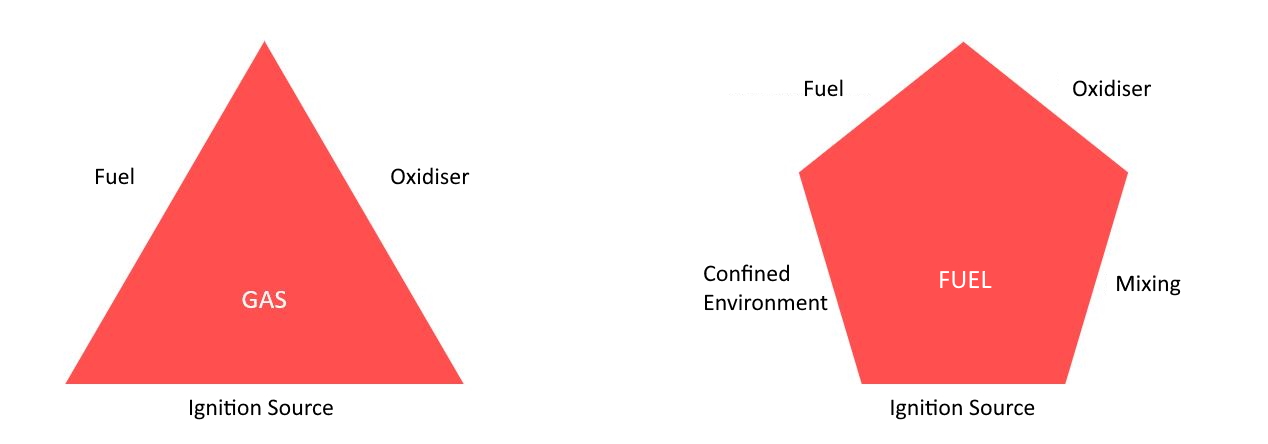

In the presence of gas, three elements must be present to generate an explosion: fuel, oxidiser and ignition source. For this reason we speak of the fire triangle.

In the case of dust, on the other hand, we speak of the explosion pentagon, since, in addition to the three elements mentioned above, a confined environment and the mixing of fuel and oxidiser are also required for an explosion to occur.

However, explosive conditions are not the only assessments to be made in the case of applications with explosion risks. Without going any further in this article, more detailed information on explosions can be found in the article on explosive dusts.

ATEX meaning: final conclusions

In this article, we have provided an overview of the meaning of ATEX and the explosions that can occur in industrial settings. In order to guarantee health and safety at work and protect the environment, it is essential to equip oneself with systems and machinery that comply with the laws described above.

In this regard, it is essential to have air extraction and abatement systems equipped with all the necessary components to reduce the impact of a possible explosion. We have been designing these types of systems since 1979, guaranteeing our customers maximum effectiveness and efficiency! Contact us to schedule a free site inspection and receive an ad hoc estimate.