Mill scale removal: a technological system

A cleaning system applied to steel pipe production lines

Steel pipes production

Today we will talk about a company which is part and parcel of a Russian leading group working in the iron and steel industry. In particular, our customer is an expert in the production of steel welded tubes used in the heating systems, water pipelines, oil and gas pipelines, in the building industry and other sectors.

The company has contacted us in order to remove the mill scale detaching during tubes high temperature transformation.

Mill scale removal system addressed to Russia

As a result of our opening meeting, our skilled staff has carried out specific technical inspections, in order to verify their real condition and to examine their customer’s needs. As previously mentioned, the company is specialised in the production of steel pipes of various diameters and lengths, thus it needs two mill scale removal machine to employ in two pipes production lines. Since pipes have different features, the extraction systems must communicate with the production lines and adjust to all the products’ size.

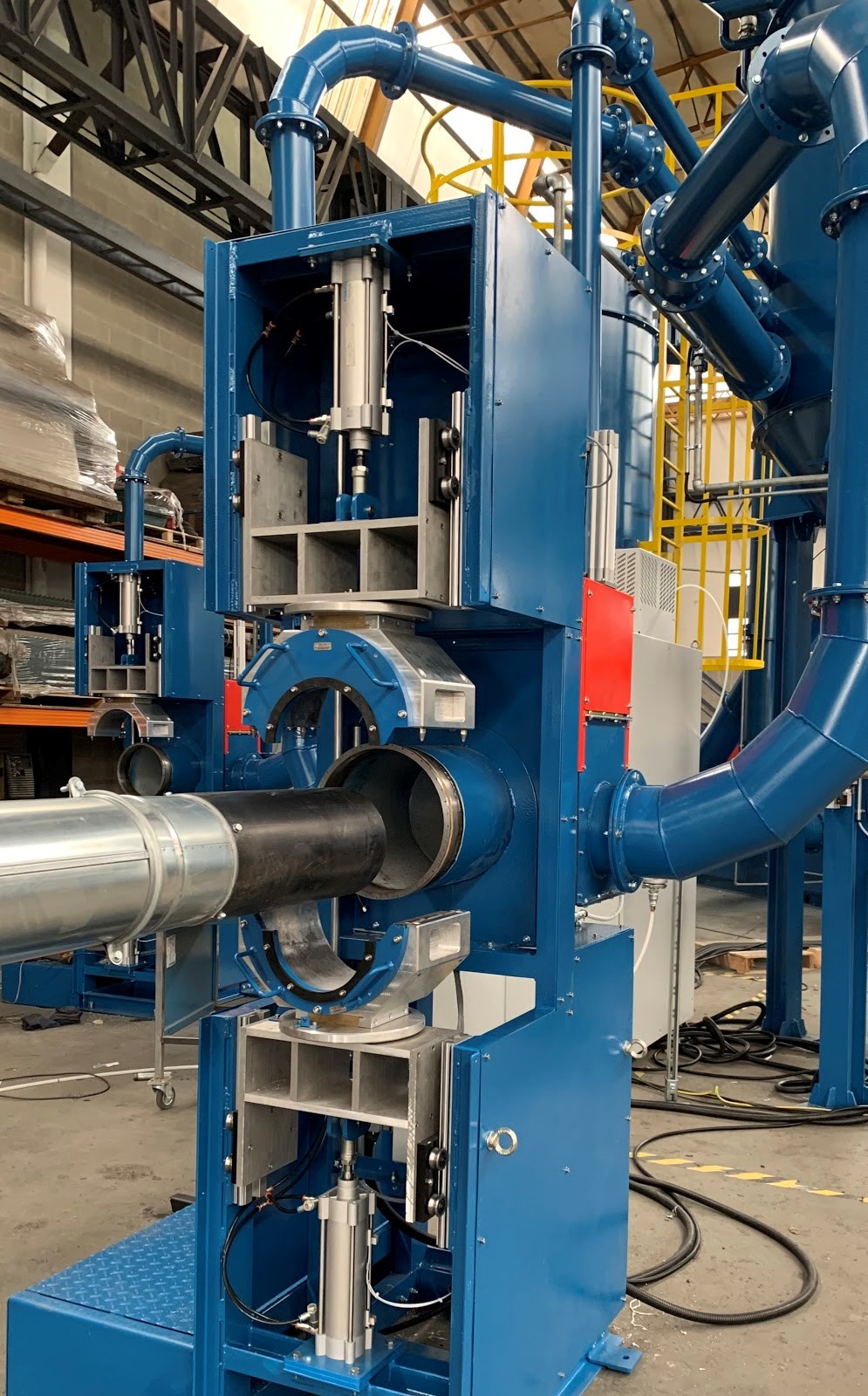

Considering their specific needs, Tecnosida® has planned and created two extraction systems, in order to recycle the mill scale. Each of them includes:

Auto-balancing clamping tong machine

It has been designed to close off the pipe and to allow the mill scale to be extracted. The clamping tong machine moves automatically through electro pneumatics cylinders. The supplied tongs have various dimensions to adjust to the different pipe’s diameters.

Centrifugal fans

Considering the different pipe’s features, each system has three sizes of centrifugal fans with different powers (11 – 30 and 45 kW). This solution allows us to use the most suitable fan according to the diameter type of the pipe in the works. The 11 kW centrifugal fan can extract the mill scale in a range between 400 m3/h and 1,300 m3/h and it is useful for small size pipes; the 30 kW one can extract the mill scale in a range between 1,300 and 4,800 m3/h and it is useful for medium size pipes; eventually, the 45 kW one can extract the mill scale in a range between 4,500 and 9,500 m3/h and it is useful for higher diameter size pipes. The group of fans is placed in a soundproofing booth, in order to reduce their noise.

Self-cleaning cartridges filter

The air flow sucked by the pipe is conveyed within the cartridges filter, where it is treated before its emission in the atmosphere. The discharge system under the filter includes a double air shutter, which allows the mill scale to be discharged ceaselessly.

Cleaning system’s operation

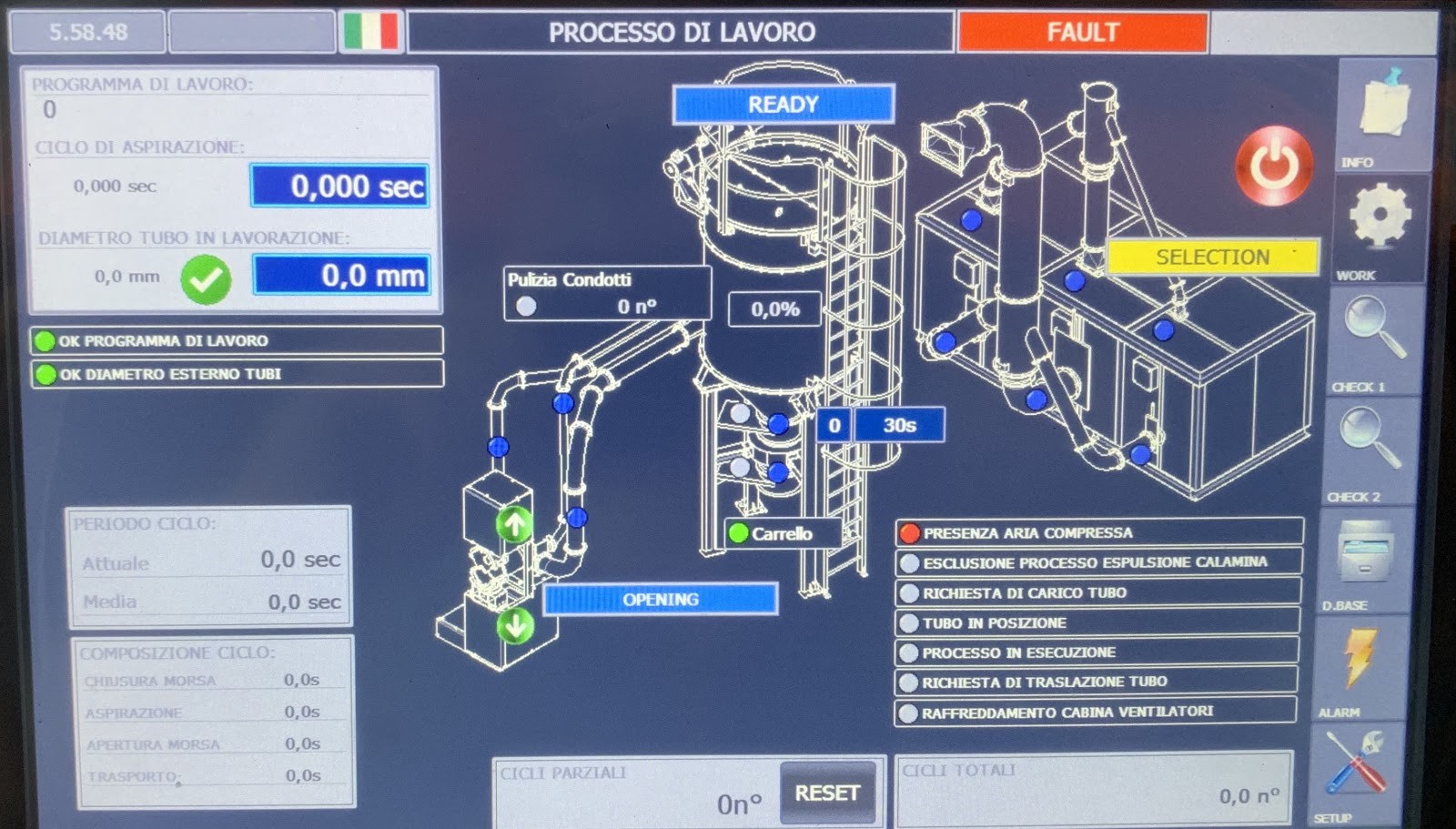

After having briefly examined the main elements included in our mill scale removal machine, it is time to explain its operation. We must underline that our system communicates and coordinates with the customer’s production line through the PLC. In particular, the mill scale’s extraction process includes the following steps:

- Preparation of the plant = during the launch of the production process, our PLC receives the specifications of the pipe. This step allows us to set up our machine, which, as we have seen before, should be equipped with its respective clamping tong.

The choice of the extractor is directly set up through the PLC of our machine, which determines the path that the sucked air flow should carry out. In this step, even all the shutters and valves present along the path are prepared

- Plant’s start up = after the set up of all the aspects seen before, the chosen fan is launched and our extraction system would be ready to receive the pipes sequence;

- Positioning and aspiration = at this point the customer’s fork lifts (machines which allow the pipes to be moved) bring the pipe in the place where they would be treated. This operation would be communicated to our PLC, which closes the pipe off with the tongs and launches the cleaning process. The intake air would be then conveyed within the cartridges filter, where the mill scale would be recycled. The entire process lasts 20 seconds.

A basic feature of our mill scale removal machine is the aspiration speed, which must be kept high, in order to remove the mill scale on steel and to avoid its accumulation in the treatment system. For this reason, Tecnosida has carefully analysed the features of the different types of pipes produced by the customer and thus has recommended the use of the three fans previously examined.

Another important aspect to keep in mind is the abrasive nature of the mill scale: the pipe’s thickness is high and it has been produced using carbon steel, in order to increase its strength.

EAC certification

As we have seen at the beginning of the article, the mill scale removal machine has been installed in Russia, thus it is an EAC-marked product. This is a mandatory certification for the importation in the Countries of the Eurasian Customs Union EACU (Russia, Belarus, Kazakhstan, Armenia and Kyrgyzstan): it certifies to the end user that the acquired product is in compliance with the security regulations of the Country.