CENTRIFUGAL FANS: blowers for gaseous flows

Blower fans for industrial ventilation

General characteristics

Industrial fans are fundamental components of plants for air pollution control. In the industrial field they must be able to deal with particular working conditions such as: 24 hours a day operations, various types of pollutants, different flow rates and temperatures.

The centrifugal fans exploit the centrifugal force for the transport of the aeriform flow. They are composed of a shell having the perimeter shaped like a flat spiral (called cochlea) in the center of which the centrifugal fan rotates. This is provided with blades (arranged circularly in the direction of the rotation axis) which provide a rotary movement to the air interposed between them. For centrifugal force, the air is projected towards the outside of the fan to be collected and conveyed into the cochlea, and exit from the discharge outlet. Specifically, in this type of fans, the flow direction is centrifugal (from the center to the outside): the air enters axially (parallel to the rotation axis) and then it is deflected 90 ° in the radial direction.

Centrifugal fans for industrial ventilation: classification

Centrifugal fans can be divided into two different macro categories: light and industrial. Both can be made of stainless steel or painted carbon steel and are also suitable for the treatment of aggressive pollutants. Industrial blowers, however, differs for its greater strength (the cochlea and the structure are electro-welded) and for the greater versatility deriving from the use of the belt transmission which changes the impeller turns adapting them to the system requirements.

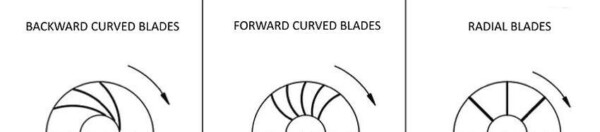

Industrial exhaust fans can also be classified according to the direction of the blades in relation to the rotation direction of the fan. The arrangement of the blades represents a detail of fundamental importance as it affects the performance and the field of application of the fans. According to this classification we have centrifugal fans:

- backward curved blades = they are characterized by high efficiency, low noise and limited energy consumption. These characteristics make them suitable for use in presence of medium / large volumes of clean and / or slightly dusty air. In this type, the blades are turned backwards and can be of constant thickness or with a wing profile (which increases the performance);

- forward curved blades = they have a slightly lower performance, but are characterized by the ability to treat dusty air and gas flows. The range of flow rates and pressure available is very wide and suitable for different uses;

- radial blades = they are noisier and have lower performance than the previous ones, but they are effective in conveying air and gas containing powders, granular materials and wood chips (open bladed version).

Industrial exhaust fans are also produced in the scirocco blade version. This type is characterized by compactness, cost-effectiveness and ability to deal large quantities of air, but have a relatively low yield. They are also realized with double suction.

Centrifugal fans: characteristic curves

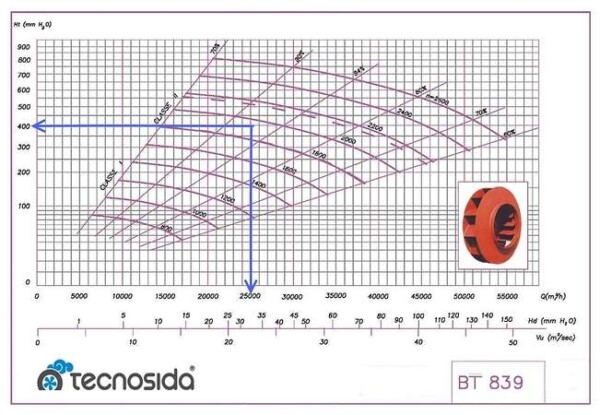

In the industrial field, the flow rate and the prevalence of the system must be taken into consideration when selecting the centrifugal blower. Starting from them, through the characteristic curves, it is possible to calculate the efficiency and the fans turns, to find the most suited according to the different situations.

The characteristic curves depend on the design of the fan and the cochlea and are mainly influenced by the curvature and the angle of application of the blades.

For example, we report the characteristic curves of a backward-bladed centrifugal fan:

The air flow rate in m3/h (Q) is indicated on the abscissa axis, while the prevalence (pressure) in m/m of water (Ht) is indicated on the ordinate axis.

From the diagram we can understand that, at a flow rate of 25,000 mc/h and at a prevalence of 400 mmdca the fan is characterized by a yield of 82% and 1930 rpm.

Centrifugal fans: optional available

- spark-proof / anti-ignition version compliant with UNI ISO 13349: 2009 and ATEX version in compliance with directive 2014/34 /EU. Both versions are suitable for use in potentially explosive atmosphere (explosion proof fan);

- inverter to adapt the impeller speed to the needs of the system;

- construction in special anti-abrasive materials;

- special constructions for high temperatures

Contact us for more information!