Volatile Organic Compounds (VOCs): filtration and abatement

Analyze with us the best technologies designed for VOCs abatement!

VOCs – How to act?

In a previous article (click here to read it) we examined the VOCs; in particular, we saw the meaning of the term, by which classes of compounds are characterized and environmental / health problems they can create.

From these considerations, questions arise spontaneously. How is it possible to intervene in industrial processes to break down the VOCs? What technologies do we have?

The goal of this article is just to give an answer to these questions. We will examine the various technologies available and how they can be used in industrial processes.

Let’s start with an interesting solution: the active carbon filtration, based on the chemical and physical process of adsorption.

Activated carbon filter

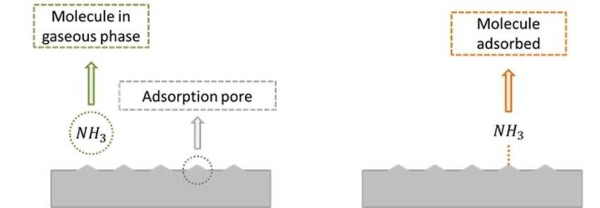

The adsorption is a very important phenomenon, which allows the accumulation of substances on a solid surface. Specifically, between the molecules present in the fluid phase and the solid surface are generated of intermolecular bonds (physical adsorption) or covalent / ionic bonds (chemical adsorption).

This phenomenon allows a separation of the molecules of interest from the fluid phase, until the surface of the solid material is fully saturated.

So, what material should be used for this application? At an intuitive level, we can deduce that the adsorption of chemical species is more favored the greater is the contact surface between the same molecules and the solid. It is necessary therefore the use of a material characterized by high porosity and a high specific surface area (per unit of volume).

An excellent material that meets these requirements is the activated carbon. This substrate is first generated by a high carbon content, by means of chemical or gas activation processes.

Placing the active carbon within a suitable apparatus, and by imposing the passage of the gas stream through the coal itself, it realizes the separation of the VOC present in the fluid phase. This is the principle behind the activated carbon filter.

On the basis of this technology, Tecnosida® has realized the Chemsorb® filter, used with success in various applications like:

- protective coating with specific polymers

- in the production of specialty and intermediate of chemicals industry

- in the demolition of aliphatic vapors and styrene …

- … and many more!

We have examined the adsorption phenomenon, which typically involves a fluid phase and a solid phase. What if instead we consider two fluid phases, specifically a gas and a liquid? Even in this case it can take place an exchange of matter, according to a physical phenomenon called absorption. Let’s examine it in more detail, with the equipment that uses the operation: the wet scrubber.

Wet scrubber

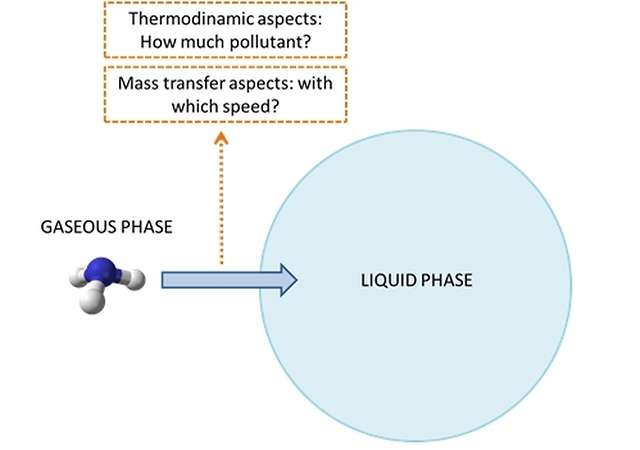

The absorption consists in the passage of chemical species from a gaseous phase to a liquid phase. In the analysis of this phenomenon it is of highly importance to consider two different aspects:

- The thermodynamic aspect: in other words, which is the maximum amount of pollutant related to a specific chemical species that the liquid phase can absorb? The answer to this question depends on many factors: temperature, pressure, concentrations and chemical-physical characteristics of the involved substances. It is possible to add reagents to the liquid phase to increase its absorption effectiveness towards the species to be treated.

- The kinetic aspect: in other words, how fast is the process of transferring the pollutant from the gaseous phase to the liquid phase? This aspect results to be profoundly influenced by the fluid dynamic conditions, by concentration gradients that develop and from the surface of the gas / liquid contact.

On the basis of the considerations made, now are built equipment that promote an effective contact between the gaseous phase and the liquid phase, with the purpose of transferring the polluting species. This type of equipment is called wet scrubber.

The embodiments for wet scrubbers are different, and are strongly based on testing and calibration of the most effective conditions. Tecnosida® has developed considerable know-how, which has enabled it to develop WETCLEAN, a wet scrubber design on the specific needs of your production process. See how we applied WETCLEAN in a production process, to reduce VOCs and dust.

Until now we have talked about absorption and adsorption, which allow you to remove molecules from the initial gas stream.

Are there technologies that, instead of exploiting the removal of the compounds, are based on the transformation of the same compounds into harmless molecules?

The answer is yes, and a technology that takes advantage of this principle is the thermal oxidation applying our Oxither.

Thermal oxidizer

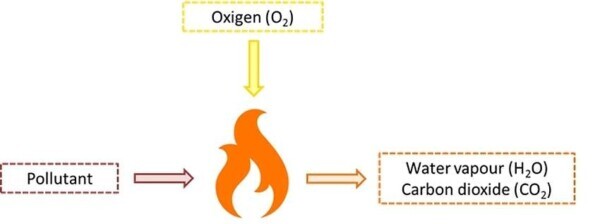

The thermal oxidizer allows to transform the VOCs in the classic of the total combustion products (carbon dioxide and water), and other by-products due to the types of atoms present in the molecules to be treated. Combustion is an exothermic process, and tends to occur spontaneously when the composition of the air / fuel mixture is within flammable limits.

This condition is very dangerous so for this reason all the combustion processes are taken into a strictly controlled to avoid problems and keep the process safe.

In particular, thermal oxidizer appears to be composed of:

- A combustion chamber where the combustion take place

- A heat exchanger, which allows to profitably use the heat developed in this process. In consideration of the type of heat exchanger the thermal oxidizer could be called recuperative if a air/fumes heat exchanger is adopted or rigenerative if a ceramic heat exchanger is adopted

- In some case a catalyst, which allows to increase the speed of the oxidation process making the oxidation possible at lower temperature (350 – 500°C instead >750°C of the other thermal oxidizer).

It is important to highlight the fact that the thermal oxidizer is an appropriate solution if:

- The concentration of VOC is sufficiently high: in this circumstance the heat developed by combustion allows the self-sustaining process from the energy point of view, with consequences lowering of the operating costs, avoiding the consumption of auxillary fuel.

- The VOC molecules are predominantly hydrocarbon. If other volatile molecules should be present in significant percentages in the combustion process, other polluting specied could be generated For example, you want to oxidize a stream containing a significant amount of halogenated hydrocarbon . The combustion process would lead to the formation of hydroloridric acid (HCl), and therefore by a pollutant you would get another pollutant. When this happen a special thermal oxidizer must be built but the problemi s solved putting a wet abatement (wet clean) system downstream

Therefore, we analyzed after thermal combustion, active carbon filtration and wet filtration. What other technologies are available for VOCs?

Are there any specific equipment that allow you to treat a particular class of VOCs: odorous molecules. These species frequently have an unpleasant impact on the olfactory and cause complaints from those living near the release site. We will see what new items are the odorous molecules and what are the technologies that are useful to treat them.

See you soon with new valuable information!