Bag Filters Vs Cartridges Filters

Bag filter or cartridges filter? Which technology is most suitable in the different industrial contexts? Read our article!

Bags vs. cartridges on dust filtration

In the context of industrial processes, there are various technologies that allow the treatment of dust. On our site we have already talked about this aspect, but in this article we want to focus on two technologies and on a very common question: is it better to use bag filters or cartridge filters? Let’s start by saying that both technologies use mechanical filtration. What does this term mean?

The separation of the particulate takes place by passing the gaseous stream through a specific filter surface, which retains the particles and separates them from the stream. Although the process is extremely simple, there are numerous solutions that apply this principle. In particular, both bag filters and cartdriges filter operate according to mechanical filtration: the difference lies in the morphological / structural characteristics of the material used and in some construction features. Here we have the comparison of our interest! Is it better to choose the bag filter or the cartridge filter? Which of the two allows to obtain the best performances? What are the differences? Let’s start with our analysis.

Bags and cartridges: Operating principles and distinctive features

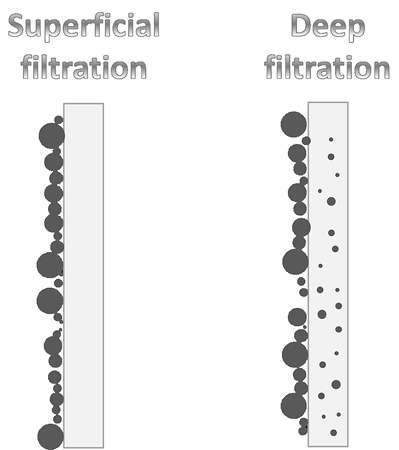

Bags or cartridge filter media have similarities and differences. The first thing we can notice is that, as previously shown, they promote a mechanical filtration. In other words, they mechanically retain the dust present in the gaseous stream. A key question is: how does this happen? To answer, it is appropriate to introduce the difference between superficial and deep filtration.

What’s the difference? As you can see in the image, the materials designed for the superficial filtration block the particles on their surface, while those designed for deep filtration allow the penetration of particles within their own thickness. Frequently the accumulated particles act as an additional filter element, and thus allow to increase the separation efficiency. It is important to highlight that, compared to an increase of efficiency, there is also an increase of the pressure drop, which make necessary to clean or replace the filter element. As you may have guessed, given the lower penetration of particles, the materials that promote surface filtration are easier to clean and last longer. On the other hand, materials that promote deep filtration are difficult to keep clean. The cartridges exploit both of the filtration mechanisms described above: surface filtration, for example, is generally applied in sandblasting processes, with the use of paper cartridges. Bags, on the other hand, use only deep filtration. Before talking about the factors to take into consideration to choose between a bag or cartridge dedusting filter, it is necessary to do a in-depth analysis on the characteristics of the filter elements.

Let’s start by saying that both the bags and the cartridges can be made in different materials, sizes, shapes and with different specific weight of the fabric. The materials used are typically of a polymeric nature, with surface treatments that make it possible to guarantee certain performances in specific contexts. As for the characteristics of the filter elements, we can summarize them in the table below:

| Data | Cartridges filter | Bag filter |

|---|---|---|

| Diameter (mm) | From 115 to 320 | 125 (our standard) |

| Height (mm) | From 600 to 2.000 | From 2.000 to 3.000 (our standard) |

| Specific weight of the fabric (g/mq) | From 130 to 290 | From 300 to 550 |

| Surface (mq) | Wide choice from 1.5 to 25 | From 0.8 to 1.2 |

As we can see in the table, the bags usually have a higher specific weight and thickness of the filtering fabric than the cartridges and are characterized by greater filtration efficiency.

As for the filtering surface, the cartridges have a greater extension than the bags therefore, with the same filtering surface, the cartridge filters are less bulky. However, the cartridges are characterized by a folded conformation which influences their filtration capacity: placed in depression, the folds tend to compress with a consequent reduction of the filtering surface. Furthermore, this conformation causes the powderto insinuate itself between the folds, clogging the cartridge. The bags, on the other hand, having a circular-flat conformation, are easily cleaned by a suitable automatic cleaning system which makes them efficient even in the presence of high quantities of dust.

Let’s move on to a practical question: how is it possible to choose between a bag filter and a cartridge filter? What are the parameters that allow you to choose one rather than the other? Let’s see it together

Bag filter or cartridge filter: this is the question!

In the context of the choice between bag filter and cartridges filter, there are many factors to be taken into consideration to make the choice. Among these we can include:

- Process flowrate: this parameter is very important to make the choice because it affects the sizing of the equipment and therefore related costs. Empirical rules suggest that cartridge filters, in contexts that allow their use, are typically cheaper than bags filters. This is a general rule: nothing replaces adequate assessments and considerations in each specific context;

- Dust load: concerning the load of powder, the comparison sees the bag filters as winners. As we have already seen in the previous paragraphs, the filter bags can be used in a very wide range of dusty load. Cartridges, on the other hand, due to their conformation, are extremely functional in contexts characterized by a limited concentration of dust;

- Nature of powders: also with regard to the nature of powders, bags show a greater versatility than cartridges. For example, in case of fine and very fine powders (talcum, graphite…) it is generally not recommended to use a cartridge filter;

- Flexibility: in accordance with the previous considerations, the bag filter have greater flexibility with regard to any variations in the production process. When it operate in extremely precise and stationary conditions, after appropriate evaluation, it is possible to opt for the cartridge filter;

- Operating costs and maintenance costs: frequently, in the purchase of air treatment systems, the cost of the system or of the equipment itself is evaluated. This analysis, which takes into consideration only the initial investment, is reductive and not very functional. A good purchase analysis must also evaluate the operating costs of the plant maintenance needs. What do these costs translate into, in practice? Typically, the main cost items are the electric consumption of the fan and the maintenance and replacement cost of the filter media. Regarding the electricity consumption, it is a function of the operating flow rate of the fan and its prevalence (helpful to overcome the pressure losses of the pipes and the filtering systems). With regard to the replacement costs of filter materials, they are a function of the efficiency of the cleaning system applicable to it: initially more expensive filter media have a more effective cleaning possibility, and therefore last longer. How do these considerations apply to bags and cartridges? As we have seen, filter bags are easier to clean than cartridges and for this reason they are characterized by a lower pressure drop and lower energy consumption.

Cartridge filter vs. bag filter: advantages and disadvantages

In the following table we summarise what we have seen focusing on the main advantages and disadvantages of the bag filter and the cartridge filter.

| Product | Advantages | Disadvantages |

|---|---|---|

| Cartridges filter |

|

|

| Bag filter |

|

|

Bag filter or cartridge filter: what to choose?

Considering what we have said, what is the best choice? Bags or cartridges? The answer to this question does not exist because to make the choice you have to evaluate the individual situations. In fact, there are different industrial processes, with different operating conditions and each with its own specific needs. The choice of the filtering equipment to use is to be made on the basis of careful analysis and a proper design.

Discover our Case History: you can find a series of applications of our technological plants, to discover how they work and to examine the many industrial contexts in which they can be used.

See you soon with new interesting articles!